| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Tongxin |

| Model Number : | Non-standard |

| Certification : | IS0 |

| Price : | Negotiable |

| Delivery Time : | 15-30days |

| Payment Terms : | T/T,L/C,Western Union,Paypal and MoneyGram |

Water-cooling vulcanizing machine (hereinafter referred to as vulcanizing machine), small in size, light in weight, common three-phase power supply, uniform temperature of hot plate, uniform pressure of water pressure system supply (1.0~2.0mPa), equipped with light automatic electric control box, The connection between the electric control box and the main unit is completed by the integrated plug-in and multi-core cable. It is easy to operate and reliable. It is widely used in metallurgy, mining, power plant ports, building materials, chemical industry and other non-explosive gases and harmful gases that can corrode metals. On-site vulcanization of canvas, nylon, and steel cord transport tapes, and vulcanized joints for special properties such as anti-corrosion and heat resistance. Moreover, as long as the equipment has a common tap water source at the site, the heating plate can be rapidly cooled by water after the vulcanization is completed. It can greatly improve the efficiency and improve the quality of the tape joint. It is generally cooled from the vulcanization temperature to 60 ° C for 20 minutes, and the cooling water source pressure is ≥ 0.2mpa. The quality of the tape joint directly affects the working efficiency of the tape, the effectiveness of use, the service life, especially the current long distance, and the high-strength conveyor belt is more important. Therefore, the DJSL type electric heating tape vulcanizing machine is indispensable in the current tape transportation machinery. Auxiliary equipment. The components of the water-cooling vulcanizer are light and can be moved by hand. The power and water source should be considered before installation. Use a special water pipe to connect the tap water source with the upper and lower heating plate cooling water pipes of the vulcanizer, but do not release water for a while. At this time, start the constant temperature to the end of the vulcanization constant temperature time. At this time, open the tap water and pass the water to the hot plate. When the temperature drops to the process value. When the water is disassembled, the vulcanization operation is completed.

The quality of the tape joint directly affects the working efficiency of the tape, the effectiveness of use, the service life, especially the current long distance, and the high-strength conveyor belt is more important. Therefore, the DJSL type electric heating tape vulcanizing machine is indispensable in the current tape transportation machinery. Auxiliary equipment.

The components of the water-cooling vulcanizer are light and can be moved by hand. The power and water source should be considered before installation. Use a special water pipe to connect the tap water source with the upper and lower heating plate cooling water pipes of the vulcanizer, but do not release water for a while. At this time, start the constant temperature to the end of the vulcanization constant temperature time. At this time, open the tap water and pass the water to the hot plate. When the temperature drops to the process value. When the water is disassembled, the vulcanization operation is completed.

| project/data/model | DJSL type electric heating water cooling vulcanizer parameter

table: width (mm) | specification | Heating plate size Heating plate size (mm) | Total power (kw) | Heavy weight (kg) | Dimensions Length × width × height (mm) | total weight (kg) | Configuring device | |

| Manual pump | Electric control box | ||||||||

| DJSL-650 | 650 | 650×830 | 830×820 | 9.8 | 56 | 1320×830×585 | 398 | 1 | 1 |

| 650×1000 | 1000×820 | 11.8 | 66 | 1320×1000×585 | 460 | 1 | 1 | ||

| DJSL-800 | 800 | 800×830 | 830×995 | 11.97 | 70 | 1450×830×585 | 485 | 1 | 1 |

| 800×1000 | 1000×995 | 14.4 | 79 | 1450×1000×585 | 550 | 1 | 1 | ||

| DJSL-1000 | 1000 | 1000×830 | 830×1228 | 14.7 | 82 | 1700×830×585 | 556 | 1 | 1 |

| 1000×1000 | 1000×1228 | 17.8 | 95 | 1700×1000×585 | 596 | 1 | 1 | ||

| DJSL-1200 | 1200 | 1200×830 | 830×1431 | 17.2 | 96 | 1950×830×750 | 784 | 1 | 1 |

| 1200×1000 | 1000×1431 | 20.7 | 113 | 1950×1000×750 | 900 | 1 | 1 | ||

| DJSL-1400 | 1400 | 1400×830 | 830×1653 | 23.8 | 107 | 2150×830×900 | 857 | 1 | 1 |

| 1400×1000 | 1000×1653 | 23.9 | 132 | 2150×1000×900 | 1080 | 1 | 1 | ||

| DJSL-1600 | 1600 | 1600×830 | 830×1867 | 22.3 | 120 | 2380×830×900 | 1102 | 1 | 1 |

| 1600×1000 | 1000×1867 | 27 | 146 | 2380×1000×900 | 1400 | 1 | 1 | ||

| DJSL-1800 | 1800 | 1800×830 | 830×2079 | 24.9 | 137 | 2620×830×900 | 1247 | 1 | 1 |

| 1800×1000 | 1000×2079 | 30 | 164 | 2620×1000×900 | 1500 | 1 | 1 | ||

| DJSL-2000 | 2000 | 2000×830 | 830×2303 | 27.6 | 154 | 2830×830×900 | 1385 | 1 | 1 |

| 2000×1000 | 1000×2303 | 33.2 | 182 | 2830×1000×900 | 1750 | 1 | 1 | ||

| DJSL-2200 | 2200 | 2200×830 | 830×2478 | 29.7 | 165 | 2997×830×900 | 1446 | 1 | 1 |

| 2200×1000 | 1000×2478 | 35.8 | 198 | 2997×1000×900 | 1800 | 1 | 1 | ||

The vulcanizer has a main machine (1. frame; 2. clamping mechanism; 3. horn; 4. screw; 5. nut; 6. washer; 9. heat shield 10. upper heating plate; 14. lower heating plate; 15. Water pressure plate;) 7. High pressure hose; 8. Pressure test pump; 11. Secondary cable; 12. Electric control box; 13. Primary cable composition.

1. Before the installation of the combing machine, the main parts (such as electric heating plates, pressure devices, racks, etc.) are evenly separated and separated, and the vulcanizer is temporarily transported to the site for temporary installation.

2, each separate separation of the parts, is also a frequent moving parts. Generally, the heaviest parts can be handled by two people, so it is convenient to install and disassemble.

3. Before installation, find a more spacious place on the installation of the tape conveyor. In this place, not only the indefinite operating area and space, but also the placement of the tape and the power wiring are convenient.

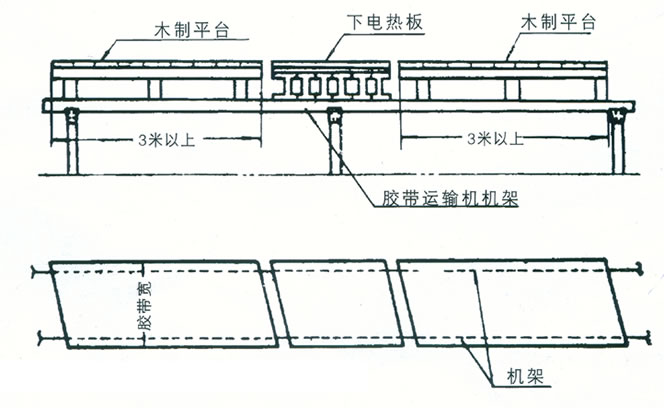

4. Before installation, on the belt conveyor installation line, disassemble the upper rollers and set up a working platform in the form shown in Figure 2. If it is glued in the field, use a canvas to build a temporary rainproof shed around the work platform.

5. Install the tools of the vulcanizing machine, the tools for processing the tape joints, the power supply wires, etc., and confirm that the glued village materials (such as cover rubber, core glue and glue) are within the validity period, the manufacturer and the production date.

6. Installation of the vulcanizer is carried out as follows:

(1) Place the single lower machine in the form shown in Figure 3;

(2) As shown in Figure 4, first place the pressure device (water pressure plate) on the placed lower frame machine; then place the lower electric plate on it. After the three are aligned, the lower electric heating plate is covered with plastic film (or talcum powder);

Note: When multiple vulcanizers work in parallel, a thin metal plate with a 0.2x50x seam length is placed at the joint of the lower electric plate.

(3) Place the tape joints that have been processed and processed well and filled with the rubber material on the lower hot plate; after finding the center line, fix the tape on both sides with the clamp plate and the clamping mechanism. Its form is shown in Figure 5;

(4), on the tape joint. Place the plastic film (or talcum powder) in the position corresponding to the lower hot plate, and then place the electric heating plate and the heat insulation board on it in order. Its form is shown in Figure 6.

Note: When multiple vulcanizers work in parallel, a thin metal plate with a 0.2x50x seam length is placed at the joint of the lower electric plate.

(5) Place the upper frame on the heat insulation board as shown in Figure 7, and align and align with the lower frame.

(6) According to Figure 8, install the pre-tightening bolts, washers and nuts in the elongated holes at the upper and lower frames, and tighten the nuts with a wrench. At this point, the main part of the vulcanizer is installed.

(7) According to Fig. 9, the quick joint of the pressure pump system is connected with the water inlet hole of the pressure device, and the primary power supply wire is correspondingly inserted into the socket of the electric heating control box, and one end of the secondary wire is inserted in the electric heating control box. On the socket, the other end is inserted on the hot plate; the corresponding one of the thermal resistance (or thermocouple) wire is inserted into the socket of the electric heating control box, and the other end is inserted into the temperature measuring hole of the electric heating plate. At this time, the vulcanization installation is completed, and the timing operation of pressurization and heating is prepared..

|